Trillo

Pictures: 3.viii.2004; 8.iii.2005

Pictures: 3.viii.2004; 8.iii.2005

| waterworks | aceitero |

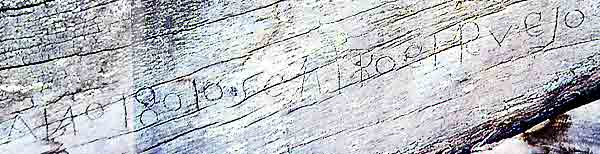

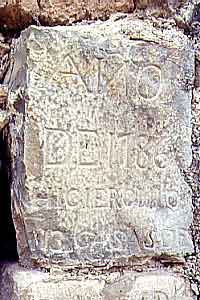

In the year 1786 this was built by the 13 families of Trillo and Don Hieronimo Salinas.

The press is placed next to the highest wall. The caracol (giant screw in pict. 7, 8) shows how high the lever could be lifted. Close to the tail of the press was a fireplace to heat water. Pictures 6, 7 and 8 show different parts of the contraption. Someone had taken away the caracol between our two visits. Pitty.

The press is separated from the rest of the building by a thick wall with two arches (pict. 5 & 13). The first arch gives access to the head of the press (5, 6): the place where the caracol was managed to force the lever down. The second arch (13) is located in the middle and gives access to the reservoirs (pilas) with the fresh oil and to the pile of mats with the olive paste.

viga) is resting on the plank protruding from this pole. The plank is fitted in a slit and could be removed. It is a second pivot! The miller knew which part of his workflow required which point as a pivot.

Our pictures show the viga

of the press in the lowest possible position. The caracol of pict. 6 doesn't show any thread below the beam which is resting

on the crossbeam of pict. 8. The tail of the press is free (pict. 2).

balsawith

ruello(9, 14). This is the place where the olives are crushed in preparation of the extraction process.

The device is most interesting because it is driven by waterpower. The stone is turned around by muscle power in the majority of the mills I've visited. Similar devices can be seen in the mills of Javierre, Santa Eulalia la Mayor, and Sieste which is the best one.

Most balsas have a flat made of concrete. The rim is low and sometimes made of bricks (e.g. Abizanda, Mipanas). Our edge at hand is much higher and made of flat stones arranged one next to another (15) just like in Sieste.