Mills in Alto Aragón - harinero, aceitero

Sieste

Sieste is situated near Boltaña.

Find Boltaña on the main road between L'Ainsa and Broto - Torla.

Coming from L'Ainsa turn left just before you enter Boltaña towards Margudgued, cross the bridge and at the

first branch turn right for Sieste. The road first meanders through the fields and then

climbs up-hill. Drop the car at the crossroads leading into the village.

Then walk back until you find the old path lined with stone walls.

Walk this path and very soon you'll see the valley of the Río de Sieste with the

mill in the depth. Continue your walk until you reach a point where the slope

is less steep. You'll notice some bigger flat stones and a diffuse path going downward.

Go down into the river bed and walk against the current to the mill.

Pictures: 27.xii.2006, 29.xii.2018

(21) Entrance of the mill; the river is left

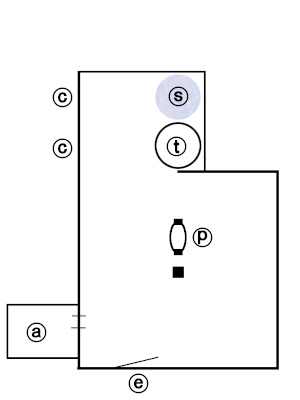

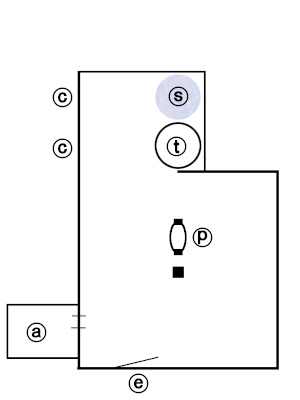

The mill has a more or less L-shaped floorplan (24) with its long leg

along the river. The entrance (21) is a low and rather broad opening in the short wall looking to the North.

The lintel consists of a large natural stone monolith.

Much of the lintel is taken up by inscriptions (22),

which are difficult to read. With the help of some school chalk we managed to decipher them:

four names, perhaps the builders/owners of the mill, and the year 1807, probably the construction year.

†

JHS

AÑO 1807

JUAN ALBAS JUAN GIL FRANco ALBAS JpHSARR R?

(22) Lintel above the entrance — JHS=Jesus Christ; FRANco=Francisco; JpH=José

From the door (24e) it's easy to appreciate the configuration of the work floor.

It is one large space without dividing walls. Central to this space is the showpiece of this mill: a prensa de barra y husillo

(bar and spindle press, 23, 24p).

The construction leans to one side like the Tower of Pisa. Attempts were made to remedy the problem with support beams,

but clearly without the hoped-for effect.

This type of press needs much less floorspace and headroom than the typical

cantilever presses of older times (see f.e.

Panillo). It is made entirely from wood and we believe it is the last example that has survived to date. All other specimens of this type that we have seen, are always partly (

Almazorre) or entirely

(

Buera) made from iron.

(23) Workfloor (picture taken from just inside 24c, looking to the entrance)

The horizontal beam, marrano

, that moves up and down in slots of the vertical posts is moved by a stick in the hole of the head on the screw (25). Due to this direct transfer and the specifics of the screw, the system still requires a lot of effort from the millers.

More modern models of the same type are equipped with a gear system and can achieve much higher pressure with less effort (

†). But there was also a higher risk of breakage: the press head was especially vulnerable. That is why more efficient systems were always made at least partly in metal .

(24) Floor plan of the mill

(25)

The head of the press carries the inscription

AÑO 1807 (26, 27)

We have seen the same year above the entrance and on the press in the mill of

Palo.

The bottom plate (28) of the press, usually made of stone is also of wood.

The base plate is elliptical and the edge is sculpted in arcs. The press has been reinforced with metal straps in various places.

(26) Head of the press — 2018

(27) AÑO 1807 — 2006

(28) Foot, regaifa

, of the oil press

The part of the building furthest from the door is much narrower than the rest (24, 29).

This is the room where the real grinding happened. We find a millstone for grain (24s, 32) and a rolling stone for olives (24t, 30).

The torno

where the olives were crushed also one of the earlier makes.

The baseplate (∅ 250cm) is lined with natural stone plates almost perfectly fitted to each other (31). The roller stone

is truncated conical. It is remarkable that its sides are not flat but show a raised edge and circular elevations (30).

(29) left: runner stone (see 32); right: olive crusher with roller stone (see 30)

(30) Truncated conical roller stone of the olive crusher —

∅ 85–90cm; thickness 35cm

(31) Flat stones bordering the olive crusher

(32) ∅ 130cm; thickness 38cm

The rollerstone (30) is moved by a horizontal waterwheel.

In our study area only a handful of mills use water power for their grinding.

Muscle power is more commonly used

for this is a region where water is a precious commodity during much of the year.

Find a similar device in Trillo, an oil mill dating from about the same time.

The runner stone (32) is an older type monolith, not one of those modern composite

stones. No other equipment of a flour mill was found.

Given the narrow space allocated to it, the flour mill was probably not

important and may have produced only limited quantities of fodder.

Left from the entrance, a narrow opening in the wall gives access

to a small and low space (24a, 21 left). It is not clear what was its purpose.

Calculations on the oil mill of

Olsón showed that pressures up to 39kg/cm

2

(41 atm) can be obtained.

See: Vanhercke, L. & Anselin, A.

— 2022 — A la búsqueda de Molinos. Volver a Olsón.

el Gurrión viii.2022, N° 168. Labuerda, I.S.S.N.: 1130-4960. pp.11–13.