La Puebla de Castro

Pictures: 11.iv.2017

Pictures: 11.iv.2017

It is good that the mill is kept as a museum, but the current arrangement and selection of items — were those wooden school benches (3) used in the mill? — clearly gives the impression that this museum site wasn't that important and that it should not cost too much effort. But still: certainly worth a visit.

The resulting olive paste was then shovelled in the open channel (5) around the grinding surface and pushed into a collecting vessel (3) by a paddle also moving together with the roller stone.

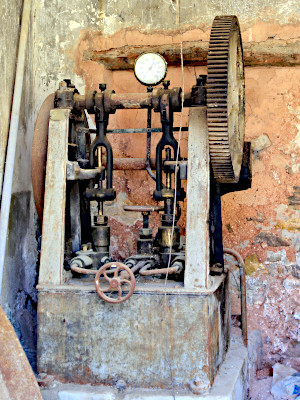

Similar devices can be seen in i.a. Banastón, Troncedo, or Mipanas.

capachos, or

esteras, which are double layered dishes (6) originally woven from

esparto(the grass Stipa tenacissima), but later made from synthetic material.

Layers of olive paste alternating with esteras were then stacked up in a trolley, vagoneta

(6).

A full load was called a pie

, but the number of capachos making a pie varied widely — dependent on factors like the type of press or even local custom — but about 3 to 5 dozen is a good guess.

Here we find only a short track both before and after the press (6, 9). Both tracks carry a trolley. I am not sure this shows the original layout. The tracks don't come near the grinder and its vessel were the paste is collected; the trolleys therefore aren't helping very much in making the work lighter.

Similar constellations of the same brand can be seen in Banastón, and Alquézar.