Mills in Alto Aragón - aceitero

Troncedo

Troncedo is a village

on the road from Tierrantona to Graus. Both should be on any map. It's

probably best to drop the car at the main plaza and — though there

is a path leading down from the village — walk the road down to the south (Graus). You'll soon see the mill

under the high tension line. A path leading to the mill starts in one of the bends.

The mill was in very good condition when we first went there and the situation became even better

since its restoration.

Pictures: 03.vi.2003, 17.viii.2011

(1) Molino of Troncedo - 2011

At the time of our first visit the mill of Troncedo

was almost invisible below the lush vegetation of mainly Ivy and Elderberry.

We entered through a double door and after our eyes adapted to the dark

discovered a spacious workplace which looked almost as if the miller

went away just a moment earlier and would soon be back from the local bar.

True, the place needed some repairs and cleaning but all the essentials were present.

Our next visit, in 2011, was a delight.

With financial support from Europe and the local council people of the Asociación Los Molinos de La Fueva had been hard at work. The mill was cleaned up and repairs were done in order to preserve the building and make the tools ready

to run. And run they do because each year a Jornada de Molienda

is now organized during which olive oil is produced in the fashion of former times.

(2) The entrance before the restoration - 2003

(3) The place is cleaned up - 2011

(4) The interior - 2003

(5) The torno and storage - 2003

(6) Embalse with storage - 2011

Olives brought to the mill are first unloaded into the temporary

storage containers (5, 6). Usually these

algorines

are found just next to the entrance

(e.g.

Banastón,

Olsón,

Mipanas)

but here storage is located

deeper inside making that the raw materials must cross the pressfloor first.

Sometimes the sections are numbered (Banastón), or a hook for a label is provided

(Mipanas), or

even an azulejo was cemented to the wall (Castilsabás)

in order to document ownership of the produce, but here nothing for this purpose seems to be present.

The first step in the process was clean the olives and then break and crush them. The latter was done in the balsa

(6, 7). That is in its simplest form

a circular flat bordered with a low ridge. A mill stone runs its rounds and by its weight converts the fruits into a homogenous mass ready for the press.

There were several issues with this process.

Power was needed to turn the stone around. People were needed who could load and unload the device

and, to make matters worse, the olives always tried to escape from the path of the runner stone.

Several approaches can be found.

(7, 8) Balsa, ruello and tolva - 2003, 2011

Usually a mule had to make the rounds and the miller

had to care for its needs: enough space to walk around (e.g.

Coscojuela were

the wall was carved out) and also a space were it could rest and eat. This often is in a separate space

(e.g.

Bara) but in Troncedo it's a room at the back of the workplace.

The entrance is visible behind the ruello in 4, 5.

Only in a minority of mills (e.g. Trillo, Sieste,

Mondot) enough water was available to do the work. More recently electricity was also used.

There is a huge evolution between the simple balsas

(e.g.

Abizanda, Coscojuela) and the last generation

with conical stones (e.g.

Torres del Obispo,

El Grado) and Troncedo

fits somewhere in between.

The stone is slightly conical (7) which reduces friction and results in a larger contact zone.

A hopper — tolva

, attached to the same axle (7, 8) — goes round together with the stone. Olives loaded in the tolva were spread out evenly without further intervention.

(9) Tolva with feeder - 2003

(10) Spoon to push the mash to collector - 2003

At the rear of this

tolva is a small door (9). The opening can be adjusted by means of a screw.

A metal rod forces olives falling through the slit outwards from the centre into the path of the

wheel. Eventually the olives reach the gutter at the periphery of the balsa.

A small plate (10) pushes the mash

towards a zone where the gutter is made broader and deeper. That's where the miller collects the

paste ready for the press. Notice the scraper to keep the ruello clean.

(11) Molino of Troncedo after its restoration - 2011

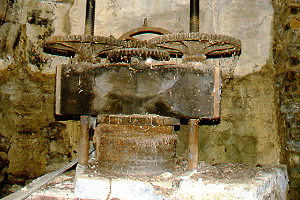

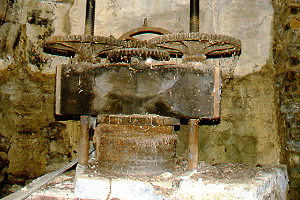

In the next step the miller

stacks the press (prensa) with circular shallow sacks (esteras) filled with the mash from the balsa.

The miller then turns the big steering-wheel to highten the

pressure and drive the oil (and water) mixture out into the first stone pila. The oil

flows then over into the second reservoir.

The block of the press is made of wood and this, together

with the date on the label, makes it (one of) the oldest we've seen of this particular brand (14).

La Maquinista

Terrestre y Maritima

Barcelona 1859

(12) Press loaded with some esteras - 2003

(13) Head of the press - 2011

(14) La Maquinista Terrestre y Maritima

The same factory is also present in

the mill of

Mipanas

— where we tell more about the company — and also in

La Muela.

A similar press with wooden head can be found in the molino aceitero

of Olsón: there is no tag of the brand though.