Banastón

Pictures: 20.viii.2013, 22.iii.2016

Pictures: 20.viii.2013, 22.iii.2016

| workplace | Vellino |

| HIJOS DE BALDOMERO NUÑEZ, S.L. | |

| Motores a gasolina y diesel Electricidad Maquinaria Elévaciones de agua | |

| Costa, núm. 14 | Zaragoza |

It was probably used to control a hammer mill — at least that is what I think of the heap of rust lying on the floor in the center of the room. Like so many mills this one also must have tried to extend its life by producing animal fodder.

The funnel (6) through which olives were fed to the system is with its 80 cm almost double the size of most found in smaller mills in the region (e.g. Mipanas, Troncedo).

The whole is still complete and in a rather good condition, but it won't last for very long anymore because with the roof now gone the tolva will soon be rotten away.

masaaccumulated. The paste was then scooped between the

capachos, or

esteras, which are double layered dishes (7) woven from

esparto(the grass Stipa tenacissima) and having a hole in the center.

Layers of olive paste alternating with esteras were then stacked up in a trolley, vagoneta

, (4 front).

A rod through the center hole served as a spinal column keeping the layers in place and the stack upright.

A full load was called a pie

, but the number of capachos making a pie

varied widely — dependent

on factors like the type of press or even local custom— but about 3 to 5 dozen is a good guess.

masa

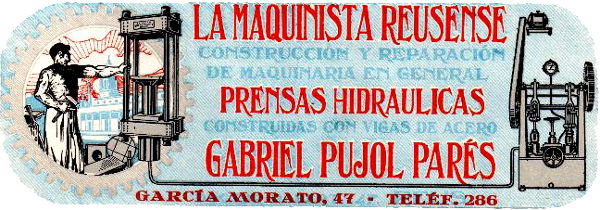

The press (3c, 13) comes from La Maquinista Reusense and it is the typical installation which is also shown in the letterhead of the company (10): a hydraulic press with an oil pump with two cilinders powered by a stationary engine by means of a belt.

At the turn of last century we've found the same brand and type still running in the oil mill in the village center of Alquézar.

The configuration at hand forms an improvement of this process.

pilas. The upper row lined with red tiles inside and white at the outside. The lower row is without. The zone below ground level was called

el infierno(the hell). The watery mix of oil and impurities arrived in the upper row and layers would form of about 30% oil on top and the rest at the bottom. Instead of scooping the oil off, the unwanted fractions would be drained from below into the containers of the

infierno. It was much more precise and convenient.

The brand was very popular and we have seen an engine of the same brand, other type though, at the playground in Palo, not that far away from Banastón.

Motores Vellino was very visible through its advertisements in magazines and newspapers and its history is connected with the early years of the automobile.

Read more about Vellino.

The old wiring of the electricity is most interesting (18, 19). The wires are held apart by spacers made of wood.

| workplace | Vellino |