The examples show that as a rule wood for the beams is debarked and then edged and trimmed in order to obtain clean and straight sides.

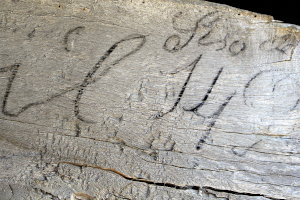

Here, in Mas de Ribera, the situation is entirely different: almost raw trunks were used. The logs have

undergone only a minimal debarking (12) and are only edged and trimmed were really necessary.

In order to make it all fit nicely together into a decent composed beam additional pieces of wood and metal were applied (11, 12 left).

The third hint can be seen at the free end of the cantilever: the

tuerca

(15)

which holds the screw which moves the press up and down. The iron rods which hold this tuerca in place on the cantilever beam

are far too long for the thickness of the tuerca. Several pieces of wood were needed (15) in order to make a solid connection. The rods, perhaps even the tuerca, may have been used elsewhere firstly.

Finally, the edge stone must have had a bad spot, or developed a fissure, and the stone was

carefully repaired (17). At no other place have I ever seen an edge stone which was repaired.