Centenera

Pictures: I.1998, 08.III.2004

Pictures: I.1998, 08.III.2004

| waterworks | harinero | aceitero | central eléctrica |

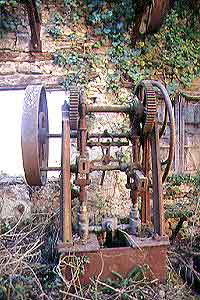

All the equipment is placed in a line against the opposite wall (13). In the corner in the depth is the roller crusher (14) (ruello) resting in its balsa. We have seen a similar contraption in the oil mill of Troncedo where we have also explained how it works. The cog wheels there are absent though, because the system in Troncedo was driven by energía de sangre (a mule as we call it).

The press is of a very modern make. The oldest type of press is of the cantilever type and asks for a long room and a high roof (e.g. Castilsabás, Trillo, Fumanal and Coscojuela). Other sites (e.g. Troncedo and Almazorre) feature a space saving device which is still based on a screw to force a plate down onto the heap of mats with olive-mash.

A similar, and more complete, system is on display at one of the plazas in Castillazuelo, a village in the Somontano de Barbastro region. It is another brand though.

La Industrial Mecánica

Cené, Carnicé Y Ca

REUS

| waterworks | harinero | aceitero | central eléctrica |