Mills in Alto Aragón - harinero, central eléctrica

Espés bajo

Espés bajo nowadays is easily reached from the

main road between

Castejón de Sos and

Pont de Suert. Coming from Castejón You'll

first have to negotiate the Collado de Fades (almost 1500 m) and then look out for the branch

towards

Abella and Espés. Do not enter the village of Espés bajo, but instead

take the road down into the valley. At some point the GR crosses the road. Follow this markings to

the west and You will soon arrive at the mill. In the likely case that You miss the GR drive the narrow

road down to the river crossing. You can now walk along the river against the current and will

soon find the mill. The mill taps water from the

Barranco de Espés.

Pictures: 16.viii.2007, 29.vii.2020

(1) Mill seen from the South.

We discern three parts in the construction. Leftmost is the

powerstation which protrudes towards the river (South). This section is lower than the flourmill

in the middle. The rightmost section with the corrugated roof was in use as a (cattle?) shed.

You first enter the shed through the steps in the middle before you'll

find the entrance to the mill proper (2) below the corrugated roof. It is a solid door flanked with

parts of milling stones (2, 3). Scan the walls of the shed and you'll find more recycled stones (4).

(5) Interior of the flour mill seen from the entrance.

Inside there is one milling unit in very good condition (5). All the essentials are still present:

a tolva, the guardapolvo (dustcover) grua with cabra (crane) and a farinal (flour box).

The whole construction rests on a hurst frame which is rahter high in order to provide enough free space for the cogwheels driven by a turbine (16).

This is probably the only place in our study area where the feeding system (7, 8) has been preserved in its entirety.

A silent (or rotary) feeder system (

†) with the big wooden tolva (hopper) on its caballete (horse), the small iron funnel (tolva chica) hanging in a wooden

traverse with adjusting screws on both ends, and even the disk that launches the grain in order to spread it evenly between the stones.

(6) The hurst frame with the turbine and the entrance.

(7, 8) The silent (rotary) feeder system.

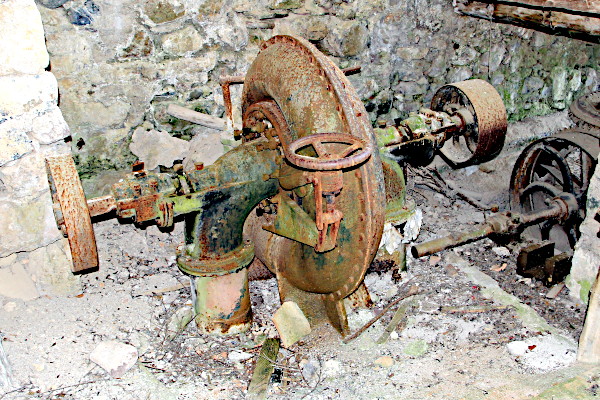

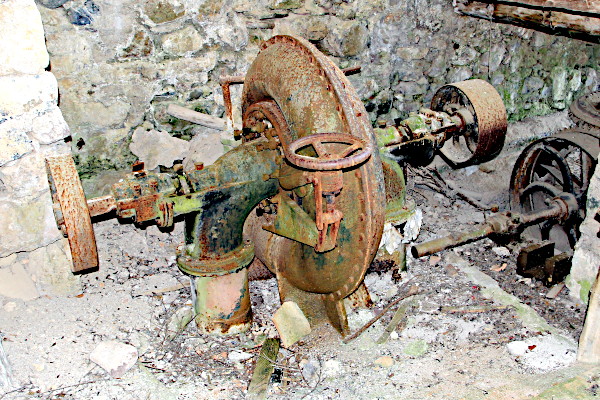

The turbine (9) that is hidden behind the hurstframe when you enter is also a remarkable specimen that we have not seen anywhere else in our study area. It is a Francis turbine equipped with two discharger tubes! I've found

it difficult to find any precise information but I think I may state that this type of turbine has a higher efficiency, and runs faster than a Francis

with a single discharge tube.

Notice that the turbine is not directly coupled to the millstone system and is equipped with two ribbon wheels with different

sizes (9). This is because the turbine has to drive two systems, each with very different requirements.

The generators found in the power stations at the smaller mills operate at 1,000 to 1,500 revolutions per minute, rarely less

(see f.e.

Ribera de Castanesa,

Arrés,

or

Puyarruego).

(9) Francis turbine with double discharger tubes.

Based on the ratios of the belt wheels driving the generator, I estimate that the turbine would have been spinning at roughly 500 rpm. That is much faster than ideal for a millstone which, depending on various factors, may have been turning about 100 revolutions.

So a direct connection was not an option and an imaginative solution was worked out.

It all starts with the small ribbon wheel (9, on the right).

This wheel is paired with a pulley (made from wood) that hangs outside the mill (10, 12) above the drain of the cárcavo.

That pulley has a much larger diameter than the one on the turbine, so we have a reduction in revolutions.

A smaller ribbon wheel is mounted on the same axle (11).

(10) Pulley hanging above outlet of underhouse.

(11) Smaller pulley on the same axle as 10, 12.

Directly in front of that wheel is a slit-shaped opening (11) in the outer wall of the mill.

On the other side of the opening (13) we see a wheel (combination of ribbon and pinion) that is part of the gearbox (16) under the hurstframe.

Here too the number of revolutions is reduced.

To prevent accidents with the ribbon, a platform (15) was installed on which

the miller could work. At the outside around the pulley (11) more parts of equipment lie scattered between

beams and roof tiles (14). Likely that this used to be a covered space with, f.e., a grain cleaner or a bolting machine.

(12) Detail of pulley in 10.

(13)

(14) Machine parts outside.

(15) Platform with flour box over the ribbon that drives the stones.

(16) Gearbox and tentering mechanism below the mill stones.

† Vanhercke, L. & Anselin, A.

— 2023 — A la búsqueda de Molinos. El alimentador silencioso.

el Gurrión xi.2023, N° 173. Labuerda, I.S.S.N.: 1130-4960. pp. 21–26.